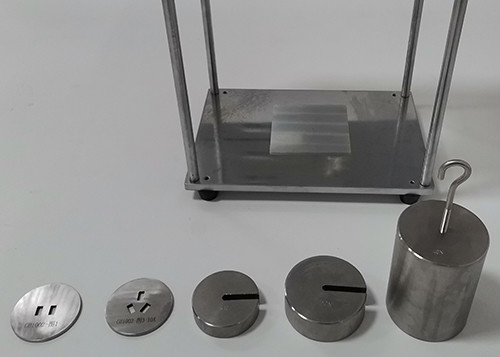

| Material: | Stainless Steel | Standards: | IEC60884 Figure 30 |

|---|---|---|---|

| Heating Cabinet Temperature: | (70 ± 2) °C | Test Station: | 1 Station |

| Weight: | 50N*1, 20N*2, 30N*1, 4N*1 | Pull Force Weight: | According To The Maximum Withdrawal Force In Table 16 |

| Function: | Testing The Firmness Of The Plug And The Plug Pin | Time Of Force Applied On Each Plug Pin: | 1 Minute |

| High Light: | 4N Verifying Test Apparatus , 20N Verifying Test Apparatus , Fig30 IEC60884 |

IEC60884 figure 30 Apparatus Plug Socket Tester To Verify Fixation Of Pins In The Body of the plug

Product details:

This device conforms to the standard of IEC 60884-1 clause 24.10 Fig30.

It is used for testing the firmness of the plug and the plug pin.

The plug is placed on a rigid steel plate provided with holes suitable for the pins of the plug.

The distance between the centers of the holes shall be the same as the distances between the centers of the circle circumscribed around the cross-sectional area of each pin in the standard sheet of the plug.

Technical parameters:

| Number of test station | 1 |

| Weight | 50N*1, 20N*2, 30N*1, 4N*1 |

| Standard socket: each one of Mexican standard for configurations: | C1.1, C1.2, C1.3, C1.4, C1.5, C1.6, C1.9, C1.10, C1.13 |

Test method:

1. Before first use, user should familiar with the relevant standards for more effective and proper using the test apparatus and completing the test.

2. The plug is positioned on the steel plate in such a way that the centers of the circles circumscribing the pins coincide with the centers of the holes. Then insert the test plug into the socket in the direction of the longitudinal axis of the pin. After that, the plug is placed in the heating cabinet with temperature (70 ± 2) °C, 1 h after, a pull force is applied inside a heating cabinet

3. Choose the clamping fixture according to the shape of the plug, and make it is firmly connected with the plug (ensure it will not loose when exert a pull force)

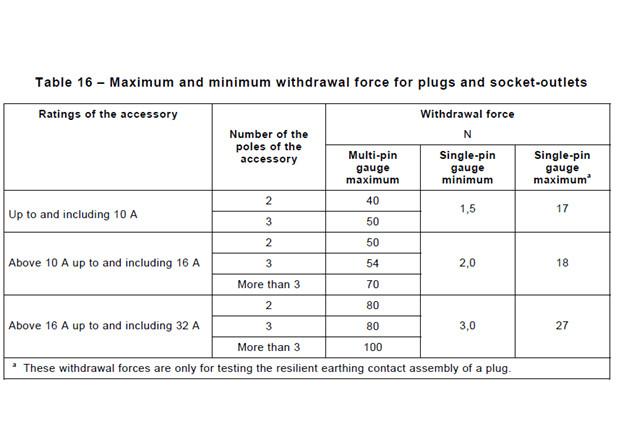

4. Choose the pull force weight according to the maximum withdrawal force as given in table 16 (can be achieved by the superposition), the weight is hooked in the ring of the clamp, handle with care, and don’t produce explosive tension.

5. The force is applied on each plug pin for 1 min, after the test, the plug is allowed to cool down to ambient temperature and it shall be verified that the displacement of any plug pin in the plug body should not excess 1 mm.

6. Pay attention to the cleaning of the device and maintenance of the sockets after the test is completed.

Table 16:

Apparatus picture: