| Standards: | AS/NZS 3112 Figure 2.8 | Name: | Application Of Force For Pin Bending Test |

|---|---|---|---|

| Function: | For Australian And New Zealand Pin Bending Test | The Distance Moved From The Point Of Application: | 7.5 ±0.3 Mm |

| Dimensions: | W*D*H=350mm *250mm* 140mm | Weight: | About 15KG |

| The Point Of Application Of The Force From The Face Of The Plug: | 14 ±0.5 Mm | Time Of The Pins Shall Be Tested: | 20 Complete Cycles |

| High Light: | Figure 2.8 Plug Socket Tester , 15KG Plug Socket Tester , 15KG pin bending test apparatus |

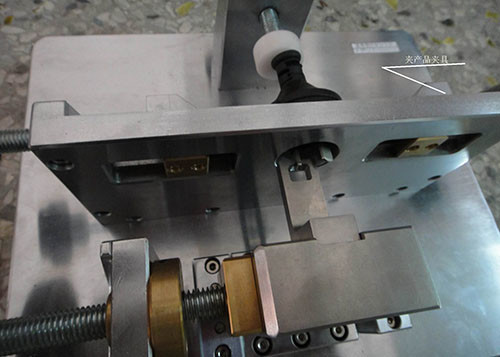

Figure 2.8 Application Of Force For Pin Bending Test AS / NZS 3112

| Figure 2.1 | dimensions of plugs |

| Figure 2.2 | apparatus for flexing test |

| Figure 2.3 | form of pin |

| Figure 2.4 | dimensions of insulation on insulated live pins |

| Figure 2.5 | pressure test apparatus for insulation on insulated plug pins at high temperature |

| Figure 2.6 | impact test apparatus for insulation on insulated plug pins at low temperature |

| Figure 2.7 | abrasion test apparatus for insulation on insulated pin plugs |

| Figure 2.8 | application of force for pin bending test |

| Figure 2.9 | mounting of plug for temperature rise test |

| Figure 2.10 | pin clamping unit for the temperature rise test |

Application

All flatpins of plugs rated up to and including 15 A shall be subjected to a pin bending test.

Three sample plugs not subjected to any previous tests shall be tested as follows:

Pins ofassembled plugs shall be tested by clamping the plug in a rigid holding blockand applying a bending force, as shown in Figure 2.8, to the pin under test.

The pins shall be straight at the beginning of the test. If there is any doubt about thestraightness of the pin, it shall be checked by the appropriate plug gaugeshown in Appendices A, B or F.

The point of application of the force shall be 14 ±0.5 mm from the face of the plug.

The direction of the force shall be along a line parallel to the face of the plug.

Active and neutral pins shall be forced towards the centroid of the plug and then back tothe starting point. On the first sample plug, any earth pin shall be forced butin one direction only and then forced back to the starting point. On the secondsample plug, any earth pin shall be forced in the opposite direction to thatused for testing the first sample plug. On the third sample plug, any earth pinshall be forced in the direction that gave the least favourableresult during testing of the first two sample plugs.

The distancemoved from the point of application shall be 7.5 ±0.3 mm, and then the pin shallbe forced back to the starting point. Any ‘spring-back’ is ignored.

The travelfrom the starting point to the end point (7.5 mm) and back to the startingpoint is one cycle (i.e. one cycle is two separate movements).

The speed of deflections shall be a maximum of 50 mm/s, without intentional delay between consecutive movements within each cycle.

The interval between successive cycles shall be a minimum of 10 s.

The durationof one cycle shall be a maximum of 60 s.

The pins shall be tested for 20 complete cycles.

ConformsTo

AS/NZS 3112:2011 +A2:2012 clause 2.13.7.2 Figure 2.8

Specifications

A. The point of application of the force shall be 14 ±0.5 mm from the face of the plug.

B. The distance moved from the point of application shall be 7.5 ±0.3 mm

C. Dimensions : W*D*H=350mm *250mm* 140mm

D. Weight : About 15KG

Ordering Information

Test apparatus for pin bending test AS/NZS 3112