| Name: | Torque Balance Test Apparatus | Standard: | IEC60884, VDE0620, IEC60598, IEC60065 Fig11 |

|---|---|---|---|

| Weight: | 2.5N*1, 1N*1 | Plug: | UL Plug*1, European Plug*1,all-purpose Plug*1 |

| The Distance From The Contact Surface And The Axis Of The Surface: | 8mm | Arm Of Force: | 0-200mm |

| High Light: | IEC60884 Plug Socket Tester , 200mm Plug Socket Tester , Torque Balance Test Apparatus |

IEC60065 Figure 11 Socket Outlet Torque Balance Test Apparatus

Technical parameters:

| weight | 2.5N*1, 1N*1 |

| Plug | UL plug*1, European plug*1,all-purpose plug*1 |

| Conforms to standard | IEC60884,VDE0620,IEC60598,IEC60065Fig11 |

| Arm of force | 0-200mm |

| The distance from the contact surface and the Axis of the surface | 8mm |

Product information:

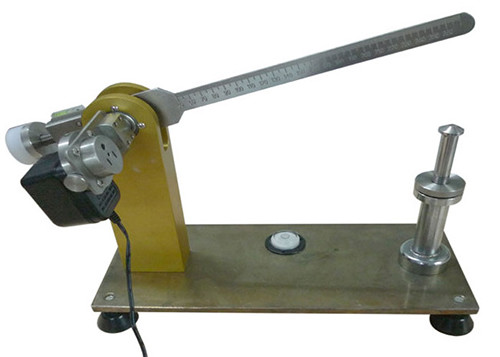

The plug torque tester conforms to the standard of IEC60065 figure 11.

It is used for checking whether the mechanical stress which occurs when the Direct Plug-in Equipment with plug pin normally insert into the socket is in the required range.

A device provided with pins intended to be introduced into fixed socket-outlets shall not impose undue strain on these socket-outlets.

The balancing arm of the test apparatus pivots about a horizontal axis through the centre lines of the contact tubes of the socket-outlet at a distance of 8 mm behind the engagement face of the socket-outlet.

With the device not in engagement, the balancing arm is in equilibrium, the engagement face of the socket-outlet being in the vertical position.

After the device has been engaged, the torque to be applied to the socket-outlet to maintain its engagement face in the vertical plane is determined by the position of a weight on the balancing arm.

The torque shall not exceed 0.25 Nm.

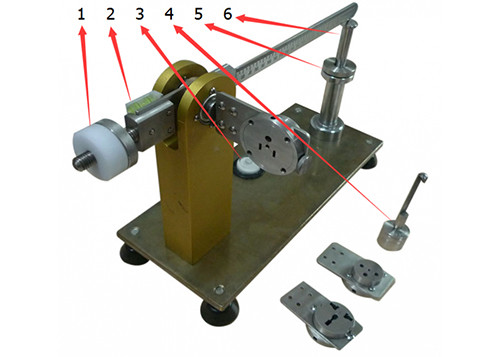

Structure

1 – balance weight

2 – measuring bubble

3 – level bubble

4 – measuring weight

5 – height regulation screw

6 – support rod

Testing steps

- Put the device on a level table, and adjust the device to horizontal.

- Hang the 4 – measuring weight on balance arm, and adjust the 5 – height regulation screw, make the balance arm in horizontal.When balance arm in horizontal, air bubble of 2 – level bubble in center position.

- Remove the 4 – measuring weight, adjust the 1 – balance weight position, keep the balance arm in horizontal position. And make the balance arm keep a distance about 1mm to the 6 – support rod.

- Install the test sample on device, tighten the screw. Now the balance arm up.

- Hang the 4 – measuring weight on balance arm. Adjust the position of 4 – measuring weight, record the position where make the balance arm level, air bubble of 2 – measuring bubble in center position, balance arm keep 1mm distance to 6 – support rod. Say the position located at 10.3cm.

- Torque measurement (1) The appropriate weight is hung on the lower scale. (2) Move the weight slowly until the balance arm is in a horizontal state.

- Torque of the sample applied to the socket: Scale value X weight For example:Torque:0.12mX2.5N=0.3Nm