| Usage: | Impact Testing Machine | Warranty: | 12months |

|---|---|---|---|

| Product Name: | Zinc Coating Testing | Function: | Impact Test |

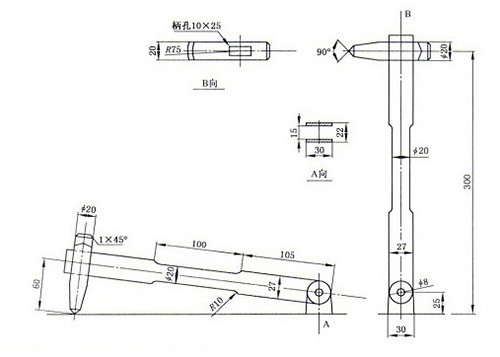

| The Mass Of Hammer: | 210g±1g | The Vertical Height From The Hammer Centre Line To The Base Surface: | 300mm±1mm |

| The Material Of The Hammer Handle: | Oak | Standard: | YDT757 |

YDT757 Drop Hammer Zinc Coating Testing Apparatus Lab Equipment

Parameters:

| The mass of hammer | 210g±1g |

| The vertical height from the hammer centre line to the base surface | 300mm±1mm |

| The material of the hammer handle | oak |

Confirms

YDT757

Product details:

This test device confirms to the standard of YDT757 drop hammer test way.

It’s suitable for the adhesive force test of hot dip galvanizing coatings. During the test, the free dropping hammer is used to hit the zinc coating to test whether the zinc coating confirms to the standard requirement. This item is appropriate for the manufacture factory like the iron tower and the quality testing department to process quality test and control.

Technical parameters:

The mass of hammer: 210g±1g

The vertical height from the hammer centre line to the base surface: 300mm±1mm

The material of the hammer handle: oak

Using method:

Using the gradienter to adjust the device and make it in the horizontal station. Then adjust the specimen and make sure that the distances from the hit points to the sample edge, corner and top side are not less than 10 mm. The hammer head is faced to the centre of rack.

Make the hammer fall down freely after the hammer handle is vertical to the base. The hammer parallelly hit five points with 4mm gaps.

And the hit points shall not be repeated in the same place. We can check the impact situation to judge whether the zinc coatings confirm the standard requirements.