| Wind Speed: | 0.2m/s | Standard: | IEC60950 |

|---|---|---|---|

| Usage: | Flame Testing Equipment | Power: | AC 220V/50HZ,220 /110 V 50/60 Hz 2 A |

| Electrode: | Platinum Electrode And Brass Electrode Each For A Pair | Electrode Dimension: | (5±0.1)×(2±0.1)×(≥12),30°slant |

| Electrode Included Angle And Distance: | 60°±5°, Distance Is (4±0.1㎜) | Electrode Pressure: | 1.00N±0.05N(digital Display Is Optional) |

| Dropping Liquid Height: | 35±5mm | Time-delay Circuit: | 2±0.1S(in 0.5A Or Larger Current) |

| High Light: | SGS Flammability Test Equipment , 220V Flammability Test Equipment , IEC60065 tracking test apparatus |

Tracking Test Apparatus Flammability Leakage Test Equipment IEC60065

Introduction:

TRACKING TEST APPARATUS is intended for determining the degree of protection against formation of conducting paths in solid insulating materials, due to the electric stress and electrolytic contamination of the surface.

This test is complex and the person performing it should be accurate and maintain good cleanliness of test equipment. The repeatability and comparability of test results depend on many different factors. Therefore we designed TRACKING TEST APPARATUS with the following goals:

- Reliability

- Maximum repeatability of test results

- Maximum comparability of test results

- Ease of operation

- Ergonomical design

Technical Specification:

| Parameter model | SC-LTT |

| Working voltage | 220V/50Hz,110V/60Hz |

| Testing voltage | 0~600V adjustable,precision 1.5% |

| Timing device | 9999X0.1S |

| Electrode | Platinum electrode and brass electrode each for a pair |

| Electrode dimension | (5±0.1)×(2±0.1)×(≥12),30°slant |

| Electrode included angle and distance | 60°±5°, distance is (4±0.1㎜) |

| Electrode pressure | 1.00N±0.05N(digital display is optional) |

| The interval of dropping liquid | 30±5S,adjustable |

| Dropping liquid height | 35±5mm |

| Dropping liquid delay | 0.2S(solenoid valve opening time) |

| Dropping liquid size | 45~50 drip/cm3 |

| Time-delay circuit | 2±0.1S(in 0.5A or larger current) |

| Short-circuit pressure drop | 8% MAX |

| Short-circuit current | 1±0.1A 1% |

| Wind speed | 0.2m/s |

| Environmental requirement | 0~40℃,relative humidity≤80%,in the place of no obvious vibration and corrosive gas |

NOTE:

1) Pannel can be in English.

2) Press button and touch screen for choose.

Main Features:

—Self contained cabinet with large viewing window and internal light

—Easy access to testing area during setup

—Built in exhaust fan

—Control panel has all controls in easy reach including lighting and exhaust

—Platinum Electrodes 99.5% minimum purity

—Alarm sounds if tracking failure occurs for more than 2 seconds.

—Safety interlock on door halts test if the door is opened

—Easy adjustment to test table height

Description:

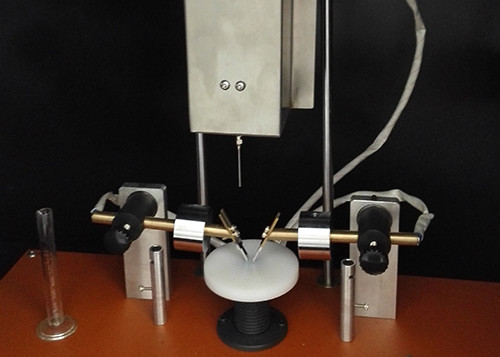

The Tracking Tester is a fully automatic instrument contained in its own cabinet to maximize the safety of the operator. Inside the well lit cabinet, a test specimen is placed on a glass plate and two platinum electrodes are lowered onto the top surface. A gauge block is supplied with the instrument to ensure the electrodes have the proper distance between them. The table height is easily adjustable to ensure the proper angle of the electrodes and height of drops. The rest of the test is controlled from outside the test chamber with the door closed. The voltage, limiting current, drip rate and number of drips are all set on the control panel. An operator should observe the test to see if a flame ignites. The instrument sounds an alarm if there is a tracking failure of at least two seconds.

Compliance:

It is constructed in compliance with IEC 60112, IEC 112, IEC 60335-1, IEC 61058-1, IEC 60065, IEC 60669-1, IEC 60884-1, IEC 60950-1, IEC 61010-1, BS 1363, IEC 60598-1, IEC 60320-1, IEC 60898-1, IEC 60400, IEC 60238, IEC 60730-1, UL746A, DIN53480, ASTM D 3638, VDE 0303, DIN 53480