| Standards: | IEC60061-3 | Warranty: | 12 Months |

|---|---|---|---|

| Material: | Mold Steel | 7006-27K-1: | “Go”gauges For E17 Caps On Finished Lamps |

| 7006-28F-1: | “Not Go”gauges For E17 Caps On Finished Lamps | 7006-26D-1: | Gauge For Finished Lamps Fitted With E17 Caps For Testing Contact Making |

| Name: | E17 Lamp Cap Gauge | Customerize: | OEM |

| High Light: | E17 Lamp Cap Go Not Go Gauge , IEC60061-3 Lamp Cap Go Not Go Gauge |

E17 Lamp Cap Gauge Go Not Go Gauge Contact Gauge Screw Thread Gauge

Gauge list:

| IEC60061-3,7006-27K-1 | E17 “Go”gauges for E17 caps on finished lamps |

| IEC60061-3,7006-28F-1 | E17 “Not Go”gauges for E17 caps on finished lamps |

| IEC60061-3,7006-26D-1 | E17 Gauge for finished lamps fitted with E17 caps for testing contact making |

Confirms: IEC60061-3

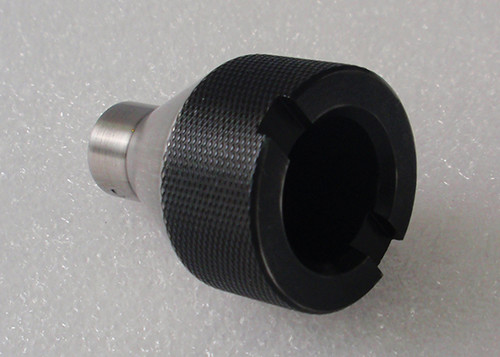

E17 7006-27K-1

Go Gauge for caps on finished lamps

Purpose: To check the maximum dimensions of the screw thread and dimension T1 min of E17 caps on finished lamps

Testing: When the cap on a finished lamp has been screwed into the gauge as far as it will go, the central contact shall touch surface X. When the lamp is removed from the gauge, at least two full turns shall be required to disengage the threads.

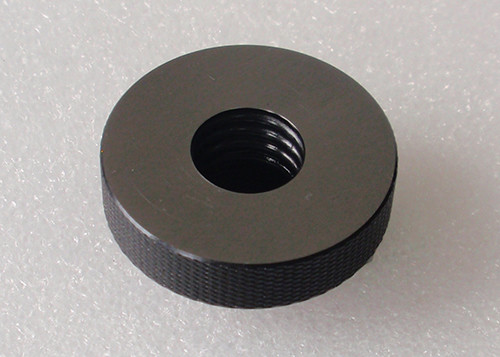

E17 7006-28F-1

Not go gauge for caps on finished lamps

Purpose: To check the minimum outside(major)diameter of the screw thread, dimension d,

of E17 caps on finished lamps.

Testing: When the gauge is placed over the thread of the cap on a finished lamp, held cap

uppermost, the central contact shall not project beyond surface X.

Only the weight of the gauge itself shall be used in the test.

7006-26D-1

Gauge for testing contact-making of lamps fitted with caps E17

Purpose: To check lamp dimension for contact-making in E17 lamphoders.

Testing: The shape of the lamp with regard to the fit in the lampholder is assumed to e correct, if the lamp can be pushed into the gauge until plane W reaches plane V or projects beyond it

Application:

Guangzhou Shice Equipment offers a wide range of gauge to meet the most common standards including those from

IEC, EN, UL, GB,DIN,VDE and others.

Such standards require the checking of size & definition etc.

These gauges are constructed from senior stainless steel and appropriate steel with a hardness of at least 60 HRC and a roughness

according to standard require.

Each gauge is supplied with a certificate of calibration.