| Standard: | IEC60950 | Usage: | Flame Testing Equipment |

|---|---|---|---|

| Glowing Filament: | Ф4mm ± 0.04mm Ni/Cr(80/20) Special Standard Ring Shape,horizontal Standing | Thermocouple: | 0.5mm Import K Thermocouple,the Temperature Resistance Of Armour Is 1100 ℃ ( Better Than The Standard Of 1050 ℃ ) |

| Ohmic Heating Temperature Of Glowing Filament: | 500 ℃ ~ 960 ℃ ( Digital Display Can Be Preset ) ,temperature Fluctuation < 3 ℃ | Specimen Pressure On Glowing Filament: | 1.0N±0.2N |

| Maximum Depth Of Heating: | 7mm ± 0.5mm | Specimen Movement Speed: | 10mm /s ~ 25mm /s |

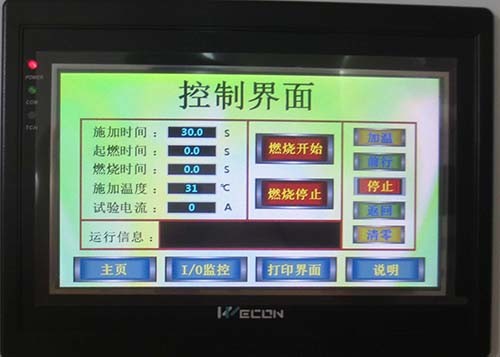

| Controller: | Touch Screen Controller | Volume Of Test Site: | ≥ 0.5m 3 Black Background ,background Illuminance ≤ 20Lx |

| High Light: | CNAS Flame Testing Equipment IEC60950 , IEC60950 Flame Testing Equipment , IEC60950 glow wire tester |

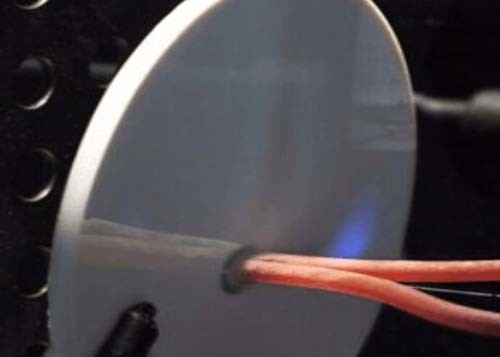

Electrical Flammability Testing Equipment Glow Wire Test Apparatus

Application:

Glow Wire tester is designed to carry out fire hazard testing on electro trchnical products.A digital temperature indicator is fitted which ,in conjunction with the thermocouple supplied ,accurately measures the glow wire temperature .The electrical circuit of the unit is fully protected by fusesand a miniaturesircuit breaker and incorporates mains on switching and push button control of output current.

Technical parameters

| Glow wire | diameter 4mm±0.04mmNi/Cr(80/20), standard |

| Temperature range | 500-1000°C ±2°C continus adjustable |

| Thermocouple | diameter 0.5mm Type K (Ni/Cr – Ni/Al), armored sheath can withstand temperature -40~ 1100°C |

| Searing Time | 30s±0.1s (OMRON H5CN-XAN-Z digital timer, 0-9999s, presettable) |

| Light-off Time | 0-999.9 s ± 0.1 s, automatic recording, manual timeout |

| Fireouttime | 0-999.9 s ± 0.1 s, automatic recording, manual timeout |

| Ironing into depth | 7mm ± 0.5 mm |

| Sample pressure | 1N ± 0.2 N |

| Test speed | 18±3mm/s |

| Control | Using single chip microcomputer + touch screen control |

| Power Supply | 800VA ,220V, 48-60Hz |

| Consult standard | IEC60695-2-10:2000,UL746A |

| Controller | 7” Touch Screen |

| Chamber | ≥0.5m |

Introduction:

1. The glow wire test chamber is an IEC60695-2-10, UL 746A, and other standards that require the use of flameless ignition source program simulation test items.

2. The glow wire test chamber heats the specified material (Ni80 / Cr20) and shape of the heating wire (nickel chromium wire of Φ 4 mm) with a large current to the test temperature (550 ℃ ~ 960 ℃ for 1 minute, and then the specified pressure (1.0N) Vertically burn the test sample for 30s. Determine the fire hazard of the finished electrical and electronic equipment depending on whether the test sample and the bedding are on fire or hold time. ), Flammability and Flammability Index (GWFI).

3. Glow wire test chamber is suitable for research, production and quality inspection departments of lighting equipment, low-voltage electrical appliances, electrical instruments, and other electrical and electronic products and their components.

Products feature:

Products feature: Adopting solenoid valve switch to control the burning depth of test sample and equipped with measuring gauge, this device has the features of exact and rapid. The test sample will break away automatically from glowing filament after reaching the set time. Adopting the original imported UK LAB K type armour(0.5) whose temperature resistance is up to 1100°(exceed 1050°of standard requirement) , this device is with accuracy temperature control.

Note: The screen can be in English.