| Standard: | IEC60695-2-20 | Purpose: | For The Ignition Risk Test Of Electrical And Electronic Products And Household Appliances |

|---|---|---|---|

| Heating Coil: | ф0.5mm,Ni80/Cr20,length:250mm±5mm ,cold Resistance 5.28Ω/m | Specimen Holder Distance And Height: | 70mm,height:60mm (the Distance Between The Holder Surface To The Tray Surface) |

| Anneal Holder Distance: | 250mm | Wire Wrapping Tension And Its Distance: | 5.4N±0.05N, 6.35mm±0. 5mm (within 31.5mm±0.5mm,coil 5 Cycle,national Standard Is 6mm) |

| Annealing Time And Power: | 8s~12s(1s~999.9s Digital Display Can Be Preset),0.26W/mm±4%(digital Display Is Adjustable) | Test Procedure: | Automatic Control, Independent Exhaust |

| High Light: | IEC60695-2-20 Flammability Test , CNAS Flammability Test , CNAS SGS flame test equipment |

Household Appliance Materials Hot Wire Ignition Independent Exhaust Tester

Parameters:

| Working voltage | 220V/50Hz |

| Control operation mode | Electrical control, button operation |

| Heating coil | ф0.5mm,Ni80/Cr20,length:250mm±5mm ,cold resistance 5.28Ω/m |

| Anneal holder distance | 250mm |

| Specimen holder distance and height | 70mm,height:60mm (the distance between the holder surface to the tray surface) |

| Wire wrapping tension and its distance | 5.4N±0.05N, 6.35mm±0. 5mm (within 31.5mm±0.5mm,coil 5 cycle,national standard is 6mm) |

| Annealing time and power | 8s~12s(1s~999.9s digital display can be preset),0.26W/mm±4%(digital display is adjustable) |

| Testing time and power | 120s(1s~999.9s digital display can be preset),0.26W/mm±4%( digital display is adjustable) |

| Specimen size | L×W×H:(125 ± 5mm) ×(13.0 ± 0.5mm) ×(0.75+0.075 0mm,1.5+0.15 0mm,3+0.3 0mm)[national standard is 0.75± 0.1 mm,1.5± 0.1 mm,3± 0.2 mm] |

| Test procedure | Automatic control, independent exhaust |

| Lighting | Equip with lighting in the test chamber, with control |

| Test chamber and dimension | >0.5³,black matte background,with exhaust fan,dimension:1100*550*1200mm,130kg |

Products Introduction:

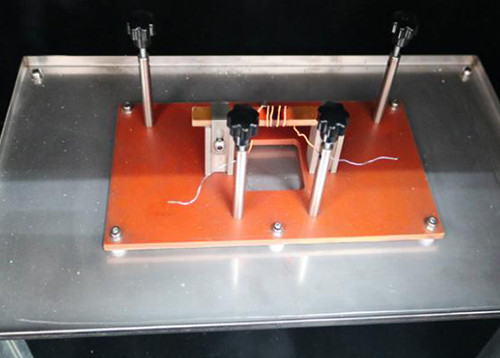

The hot wire ignition tester is designed and manufactured according to the requirements of the “Glow Wire Ignition Test Method” in relevant standards. It is suitable for the ignition risk test of electrical and electronic products and household appliances, and simulates heat sources such as hot components or overload resistors. The thermal stress caused by the ignition source in a short period of time is applicable to the quality inspection departments and related enterprises at all levels for fire resistance test.

The instrument adopts stainless steel structure, digital instrument display, convenient operation and stable performance. After the sample reaches the preset hot time, the equipment automatically stops working, the power automatic protection device and the output power upper limit automatic protection function.

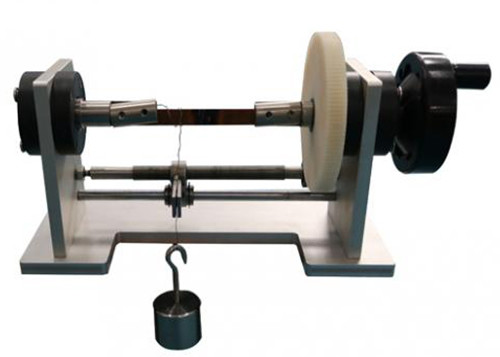

The winder designed according to the IEC60695-2-20 standard can accurately circumvent the shape of the heating wire required by the standard, and the operation is very simple.

Operating Steps

1. Preheating of the equipment: When the power is turned on, the heating power meter will display the positive and negative power parameters. The reason is that the internal power transmitter is preheating. After 15 minutes, the system will stabilize and the power meter will display Test work can only be performed with zero or minimum values.

2. Heating wire pretreatment:

a) Set the heating wire pretreatment time and select “Warm-up”.

b) Take the appropriate length of heating wire and install it in the preheating position of the fixture.

NOTE: The length is around 400mm for easy winding.

3. Install the heating wire on the sample

Intall the pretreated and cooled heating wire on the sample by the wider.

4.Normal test :

Install the sample wrapped around the heating wire on the fixture.

Set the test time, select “Test TEST”, press the “Start” button to adjust to the required test power.When the set time is reached or the output power is too large, the instrument will stop automatically.