| Usage: | Flame Testing Equipment | Electrode Materials: | The Electrode Caput Of Brass-platinum |

|---|---|---|---|

| Controller: | 7 Inch TFT Touch Screen | Electrode Distance: | 4.0mm±0.1mm,60±5°angle |

| Test Voltage: | 100~600V Adjustable, Displayed Value: R.m.s | Electrode Pressure: | 1.00N±0.05N |

| Heigh Drops: | 30-40mm±5mm(adjustable) | Dripping Nozzle: | Outer Diameter: 0.9mm~1.2mm For Solution A |

| High Light: | CNAS 600V Tracking Index Tester , CNAS 100V Tracking Index Tester , CNAS IEC 60112 Flame Testing Equipment |

IEC 60112 Lab Tracking LeakageTester Tracking Index Test Chamber

Technical Parameters:

| Electrode Materials | The electrode caput of brass-platinum |

| Controller | 7 inch TFT touch screen |

| Electrode Distance | 4.0mm±0.1mm,60±5°angle |

| Test Voltage | 100~600V adjustable, displayed value: r.m.s |

| Test Current | Current limiting 1A±0.1A adjustable, |

| displayed value:r.m.s, tolerance of 1.5% | |

| Electrode Dimensions | width: 5mm±0.1mm, |

| thickness: 2mm±0.1mm, | |

| length >12mm, | |

| end chisel-edge angle : 30°±2°,platinum. | |

| Electrode Pressure | 1.00N±0.05N |

| Dripping Nozzle | outer diameter: 0.9mm~1.2mm for solution A |

| 0.9mm~3.45mm for solution B | |

| Dripping Interval | 0-99 seconds (adjustable),the time for 44-55/1cm3(adjustable) drops to fall on the specimen shall be (30±2)min. |

| Heigh Drops | 30-40mm±5mm(adjustable) |

| Control | Using single chip microcomputer + touch screen control |

| Chamber volume | >0.5m³, black interior |

| Outer Dimensions | W*D*H=1100mm*700mm*1300mm |

| Power Supply | 800VA ,220V, 48-60Hz |

| Display panel language | Chinese + English (adjustable) |

Description:

The Tracking Index Apparatus IEC60112 is used for the determination of comparative tracking indices of solid electrical insulating materials on pieces taken from parts of electrical and electronic equipment and on plaques of material using alternating voltages. In normal use, components made of insulating material may become moist and dirty. If the impurities are electrically conducting, current will flow between parts of different voltage potentials creating a track. As a result, small flashovers may occur, which cause thermal stresses to the surface of the insulating material. The visual result of thermal decomposition of the insulating material caused by the tracking current is called the track. The interconnecting formation of carbonized material forms a tracking path, by which a lasting current conducting connection results. Thereafter the component cannot fulfill its intended electrical function in the majority of cases and parts may catch fire. The resistance of an insulating material to track formation is called the tracking resistance.

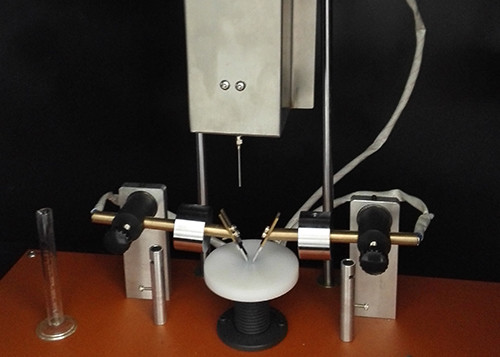

Instrument

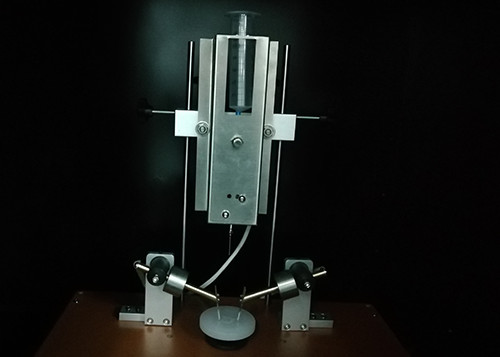

The Tracking Index Apparatus IEC60112 is a fully automatic instrument contained in its own cabinet to maximize the safety of the operator. Inside the well lit cabinet, a test specimen is placed on a glass plate and two platinum electrodes are lowered onto the top surface. A gauge block is supplied with the instrument to ensure the electrodes have the proper distance between them. The table height is easily adjustable to ensure the proper angle of the electrodes and height of drops. The rest of the test is controlled from outside the test chamber with the door closed. The voltage, limiting current, drip rate and number of drips are all set on the control panel. An operator should observe the test to see if a flame ignites. The instrument sounds an alarm if there is a tracking failure of at least two seconds.

Features

• Self contained cabinet with large viewing window and internal light

• 7″ TFT touch screen of operating system

• Easy access to testing area during setup

• Built in exhaust fan

• Control panel has all controls in easy reach including lighting and exhaust

• Platinum Electrodes 99.5% minimum purity

• Alarm sounds if tracking failure occurs for more than 2 seconds.

• Safety interlock on door halts test if the door is opened

• Easy adjustment to test table height

Application:

IEC60950 IEC60884 IEC60335 tracking index test apparatus is a fully automatic instrument contained in its own cabinet to maximize the safety of the operator and mainly used test the resistance Tracking Performance of solid electrical insulation materials when they are exposing in electric affect impurity water situation.Mainly used for determination PTI and CTI items.

Inside the well lit cabinet, a test specimen is placed on a glass plate and two platinum electrodes are lowered on the top surface.

A gauge block is supplied with the instrument to ensure the electrodes have the proper distance between them. The table height is easily adjustable to ensure the proper angle of the electrodes and height of drops. The rest of the test is controlled from outside the test chamber with the door closed.

The voltage,limiting current, drip rate and number of drips are all set on the control panel. An operator should observe the test to see if a flame ignites. The instrument sounds an alarm if there is a tracking failure of at least two seconds.