| Material: | Stainless Steel | IP Code: | IPX3, IPX4 |

|---|---|---|---|

| Pressure Gauge: | 0~0.25MPa | Standard: | IEC60529 |

| Size Of The Oscillating Tube: | R1600mm | Needle Hole: | Φ0.4mm |

| Angle Of Two Holes: | IPX3: 120°; IPX4: 180° | Oscillating Angle: | IPX3: 120°(±60°) ; IPX4: 350°(±175°) |

| Oscillating Speed: | IPX3: 4 S/time(2×120°) ; IPX4: 12 S/time(2×350°) | Water Flow: | 0-7L/min |

| High Light: | Oscillating Tube Ip Testing Equipment , IEC 60529 Ip Testing Equipment , 7L/min Ip Testing Equipment |

IEC60529 IPX3 IPX4 Oscillating Tube Waterproof Testing Equipment

Conforms to:

IEC60529

IEC60598-1

IEC 60335-1

IEC60745-1

VDE0630

VDE0632

IEC60034

DIN40050

ISO20653

IP Code of the IPX3 and IPX4

Technical parameters:

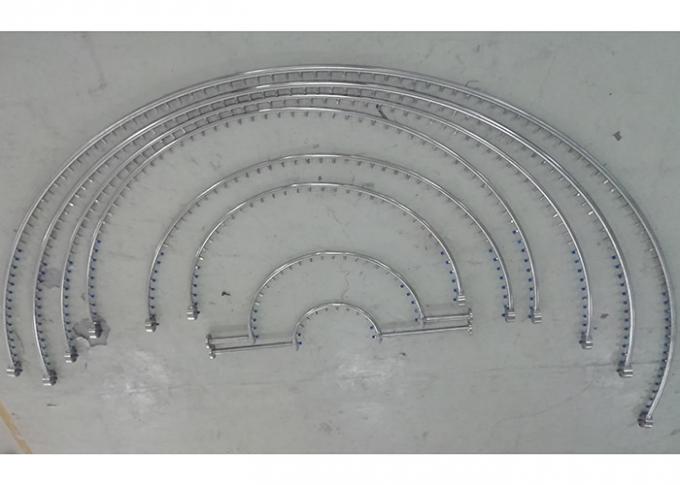

| Oscillating Tube radius | R1600mm |

| Orifice diameter | Φ0.4mm |

| Distance between nozzles | Intervak 50mm a nozzle |

| Number of holes | 100 |

| Each hole average Flow speed qv1 | 0.07L/ min. ±5% |

| Flow | 0-7L/min |

| Oscillating angle | 120°(IPX3),350°(IPX4) Or custom settings |

| Rotation mode | Always corotation/Positive and negative rotation/Spacing rotation |

| Oscillating speed | 240 degrees 4S, 720 degrees 12S back and forth (precise control), or custom settings |

| Operating | 7inch touch screen |

| Turntable size | Φ1000mm |

| Turntable load d-bearing | 350KG |

| Additional tubes | R1400mm, R1200mm, R1000mm, R800mm, R600mm |

Application:

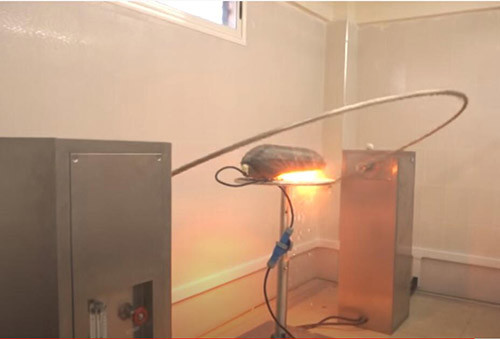

The Oscillating tube testing equipment is used for the testing of IPX3 and IPX4

The test apparatus with water proof functions, such as electronic appliances, lamps, electrical cabinets, electrical components,

car, motorcycle, electrical products (such as automotive instrument, all kinds of switches, micro motors, etc.).

Feature:

There are two models: Open type and chamber type. Using PLC control, motor drive oscillating tube to do the reciprocating motion at a certain angle, at the same time control the water flow, the turntable rotates at a certain speed, so that to make every side of the sample testing uniformly.

If for certain types of apparatus it is not possitble to wet all parts of the enclosure under test, the support of the enclosure

may be moved up or down. The hand-held test device as in figure 5 (spray nozzle) should be used as a preference in such cases.

Customer Usage Site: